PRODUCT

AVIC23

AI Vision Inspection Machine

Model AVIC23

- Size

- 1,411 x 947 x 2,045

- Selection Ability

-

Default 6 columns

Tablet & soft capsule

- Up to 200,000 tablet & Soft capsule per hour - Power Supply

- 220V or 380V 3phases, 60Hz

- Weight

- Less than 600kg

Characteristics

- Standards can be selected

- Dimension Sorting(short and long diameters of capsules)

- Soft capsules/hard capsules/tablets inspection

- Able to inspect Softgels and Hard Capsules by installing required change-parts.

- Easy to change from one product to another product

- Easy to clean

- Easy to operate

- Inspection rate: Softgel

#Oblong – 150,000 – 180,000/hour

#Oval – 200,000/hour - Camera inspects entire surface of softgels while turning them 360°

- No defects are ejected into the bin for good softgels.

- Detectable range: 50 – 100 micron

| an inspectionable product | ||

|---|---|---|

| AVIC23 | AVIC24 | |

| <Soft Capsules> | <Hard Capsules> | <Tablets> |

|

|

|

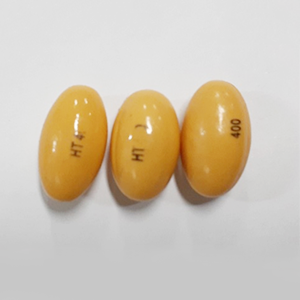

Softgels

Different types capsules(transparent))

printing defects

capsules body color defects

One or two color classification

Different types capsules(not transparent)

broken capsule

- As softgels pass through the inspection zone, cameras inspect softgels including both ends of the softgel while turning them 360° .

- Detect and reject foreign capsules and different color.

- Detect and reject stain on softgels and air bubbles or foreign material inside clear softgels.

- Detects and rejects different size, defective print and deformed shape.

Hard Gelatin Capsules

- Able to inspect entire surface by a camera while turning 360°

- Detects and rejects stain, spot, different color, print, size, split capsules and deformed capsules.

- Inspection rate: 200,000capsules/hour